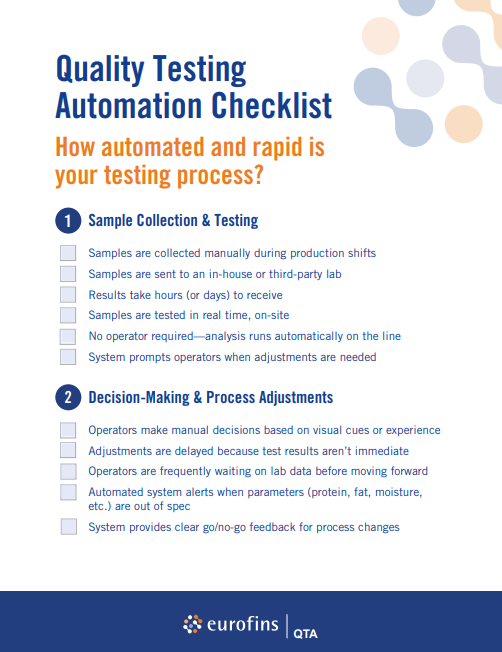

Quality Testing Automation Checklist

How automated and rapid is your testing process? Review the checklist below and tally how many statements apply to see if your operation’s processes make you a good fit for automation through managed NIR.

Sample Collection & Testing

- Samples are collected manually during production shifts

- Samples are sent to an in-house or third-party lab

- Results take hours (or days) to receive

- Samples are tested in real time, on-site

- No operator required—analysis runs automatically on the line

- System prompts operators when adjustments are needed

Decision-Making & Process Adjustments

- Operators make manual decisions based on visual cues or experience

- Adjustments are delayed because test results aren’t immediate

- Operators are frequently waiting on lab data before moving forward

- Automated system alerts when parameters (protein, fat, moisture, etc.) are out of spec

- System provides clear go/no-go feedback for process changes

Hold & Release Management

- Finished product is frequently placed on hold until lab results come back

- Decisions on held product take longer than one shift

- Product remains on hold >2 hours while waiting on results

- Real-time data is used to release or rework product immediately

- You can determine within minutes whether to keep, reprocess, or discard

Calibration & Instrument Management

- You maintain calibrations internally (or not at all)

- Instruments drift over time and results aren’t always trusted

- Calibrations, maintenance, and performance monitoring are managed for you

Reporting, Compliance, & Traceability

- Audit trails are hard to track or incomplete

- Data isn’t 1:1 linked to batches, lots, or shift production

- Automated data records every sample with user, lot, and timestamp

- You can export test results instantly for audits or customer requests

Team Burden & Resource Use

- Staff spend valuable time preparing samples, shipping, or following up with labs

- Quality teams are stretched thin managing instrumentation and methods

- Lab staff is overwhelmed by repetitive tests that are often within spec

- Plant operators receive clear, real-time answers—without calling QA

- Lab and QA teams now focus on improvements and root-cause analysis

Scoring Guide

Tally up the number of statements above that are true for your business to determine your score.

0–5 checked (automation-heavy): Your process is optimized—where could you scale or expand?

6–10 checked: You’re halfway there; automation could eliminate delays and guesswork

11–15 checked: You’re relying heavily on manual work or delayed testing—you're a perfect fit for managed NIR

16+ checked: Your system is reactive, costly, and stressful—time to modernize

Next Steps

Ready to get started? We can help.